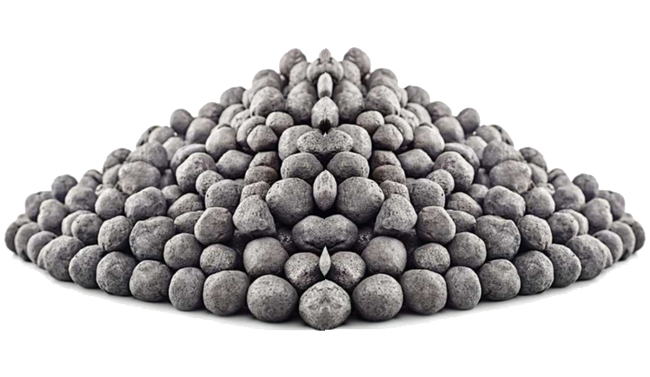

What is an Iron Ore Pellet?

The iron ore pellets are recharged in the furnace's direct reduction unit and reformed by gas at a temperature of about 800 to 870 ° C in the form of iron oxide in the form of reclaimed iron called "sponge iron". Sponge iron comes from the direct revival of iron ore, also called DRI.

The capacity of the sponge iron unit in this project is designed using 800 series technology with a capacity of 960,000 tons per year which in total requires about 1,400,000 tons of iron ore pellets as input material.

Supplying all iron ore pellets is foreseen for this project, as projected from the domestic market in Iran, and iron ore mines have created or are currently in the process of producing pelletizing capacities and can deliver the required quantities of the project.

Application of Sponge Iron

One of the most important applications of sponge iron in induction furnaces is the production of crude iron and steel. It can be said that the use of sponge iron in the induction furnaces is capable of replacing the scrap by approximately 2%. However, its application in the induction furnace requires technical knowledge and experience. The use of sponge iron is also a major development in the continuous casting of the steel industry. It can be used in almost all steel production methods. Many small and large steel plants in the country use these methods. Iran has more natural resources at its disposal for direct recovery. Sponge iron is a good substitute for iron scrap, so a high percentage of raw materials needed to supply the steel melt needed can be supplied through sponge iron instead of scrap.

The use of sponge iron in furnaces and resuscitation units has advantages over scrap iron as follows: