About Ardakan Steel Complex

Ardakan Steel Complex The country's first and largest private project for the production of sponge iron to meet the domestic demand of steel mills and steel, including the complete production chain (concentrate unit, pelletizing unit, sponge iron, smelting and steel unit). , Rolling mill) is in Ardakan, Yazd. The integrated end-product market will include both domestic and foreign consumers (mainly regional and Asian countries). The product of this project will be cold sponge iron reclaimed pellets, all of which will be consumed in the domestic steel sector, and all scrap iron consumers will be able to use this product as scrap metal for melting furnaces if necessary. To use.

The first phase of the project, Sponge Steel Iron Project, started in 2012 with an annual capacity of 96 million tons based on Miderks technology, which is approved both in terms of domestic technical capability and energy consumption and product quality. This project will be one of the most modern plants of its kind in Iran by installing a plant including a direct gas recovery module with cold output and using Miderks technology (Module 800 Series). The nominal capacity of the resuscitation module is 9,600,000 tonnes per year, which can be increased to approximately one million and fifty thousand tonnes per year as design capacity.

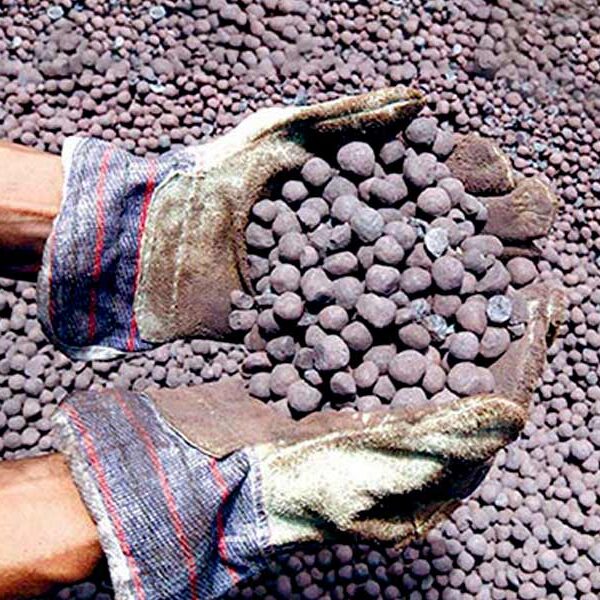

Products

The iron ore pellets are recharged in a direct reduction unit in the furnace and reformed by gas at a temperature of about 800 to 870 ° C in the form of iron oxide in the form of reclaimed iron called "sponge iron". Sponge iron comes from the direct revival of iron ore, also called DRI. The capacity of the sponge iron unit in this project is designed using 800 series technology with a capacity of 960,000 tons per year which in total requires about 1,400,000 tons of iron ore pellets as input material. Supplying all iron ore pellets is foreseen for this project, as projected from the domestic market in Iran, and iron ore mines have created or are currently in the process of producing pelletizing capacities and can deliver the required quantities of the project.

Contacts Info

Tehran office

Tehran office :No. 7, Kermanshah Alley, East Garmsar Street, Molla Sadra St, Vanak Square, Tehran

Phone : +9821 8862 6483

Fax :+9821 8862 6503

E-mail : info@arsco-steel.ir

working hours : Saturday to Wednesday from 8:30 to 16:30

Thursdays from 8:30 to 12:30

factory address

Adress: Yazd, 25 km from Ardakan Road to Nain, Next to Ardakan Pelletization

Phon : +9835 3228 6311

All rights reserved to Ardakan Steel Company.